Electric cars: 1,200 km of autonomy in 10 minutes, the revolutionary battery signed Toyota, the lithium -free battery, a revolution for the electric automobile? Numerama

Lithium -free battery, a revolution for the electric automobile

Sodium-ion batteries are not free from defects. Among the negative points of this technology, there is their energy density and their weight.

Electric cars: 1,200 km of autonomy in 10 minutes, the revolutionary battery signed Toyota

The Japanese company claims to have developed a new battery technology that promises to revolutionize the electric market. Toyota was already working on projects aimed at introducing cars with solid batteries by 2025, But his work is ultimately more advanced than expected.

The Japanese automaker revealed that it had simplified the production of the material used in these batteries, suggesting a significant advance in terms of charging time and autonomy. Toyota’s goal is ambitious: half the size, price and weight of batteries in the coming years.

Toyota wants to make electric cars more independent than ever

According to Toyota’s statements, the manufacturer has made significant advances in terms of the sustainability of its batteries. The company now claims to be able to produce a solid state battery offering a range of 1,200 km, which can be recharged in less than 10 minutes.

According to the Financial Times, Toyota plans to start making batteries in a solid state for electric vehicles at the end of the decade. This type of batteries are eagerly awaited due to their potential for reducing charging times, increased capacity and attenuation of fire risk associated with lithium-ion batteries with traditional liquid electrolyte. Indeed, these heat up much less during recharging, which makes it possible to maximize the safety of drivers.

Despite these technological advances, Toyota remains cautious to say the least, regarding his future in electricity. The manufacturer plans to manufacture 3 million electric vehicles per year by 2030, only half of which with solid batteries. Keiji Kaita, president of Toyota’s research and development center for carbon neutrality, said the company was now confident for mass produce these batteries for electric vehicles by 2027 or 2028. So we will have to wait a few years before seeing them arrive in our vehicles.

We imagine that other manufacturers of batteries such as CATL, LG Energy and even BYD will quickly react to the news by revealing their own solid battery technologies.

- Share Share ->

- Tweeter

- Share

- Send to a friend

Lithium -free battery, a revolution for the electric automobile ?

Ultra-represented, lithium-ion batteries could gradually be doubled by the emergence of sodium batteries. Cheaper, cleaner, these new batteries would be the future of the electric automobile.

Whether it is phones or electric vehicles, lithium-ion batteries are the most popular on the market. Its manufacturing in industrial quantities and at a relatively cheap production cost allows it to be very popular with brands, especially in the electric automobile sector. But this production at a reduced cost is not without consequence at the ecological level.

The sharp rise in lithium prices in 2022 also pushed the main manufacturers of battery, such as Byd or Catl, to accelerate the rate of development of other alternatives such as sodium-ion batteries. Catl presented the latest innovations on this subject at the Shanghai Show on April 16.

Lithium, a material at the heart of concerns

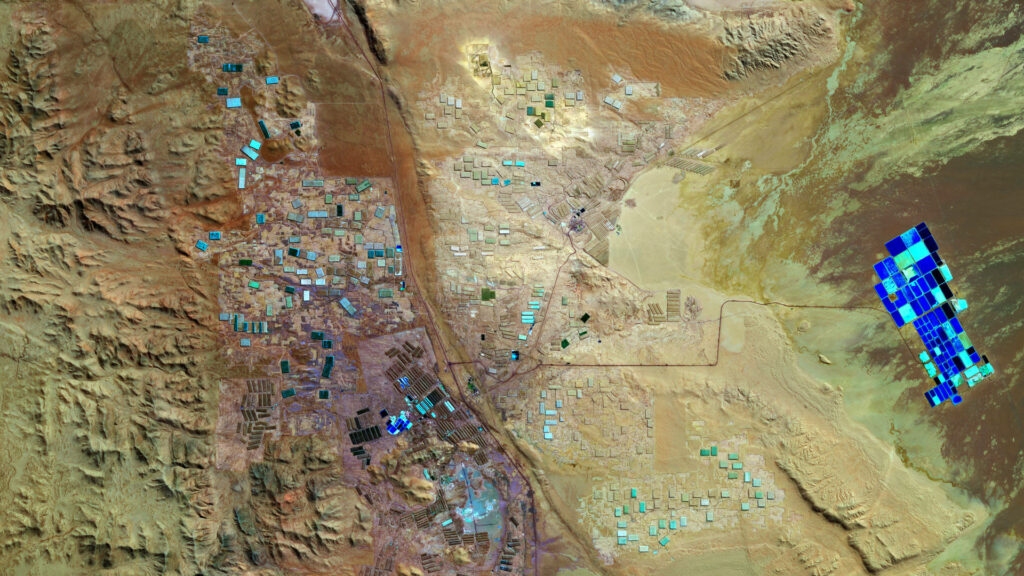

Each battery contains several kilos of lithium, mainly produced in Australia and Chile, two countries which are located far from the countries of battery production. An ecological impact in terms of material transport, but also in terms of lithium mines. The latter require a large amount of water, up to 2 million liters of water for a ton of lithium. And like many fossil fuels, the question of exhaustion of lithium resources will eventually arrive.

To deal with this problem, the engineers worked greatly and were able to develop a sodium battery. An interesting alternative on many points, both on the ecological and economic aspect, in particular thanks to technological advances.

First of all, sodium is an element that is even more present on the planet: almost 500 times less rare than lithium, while the two elements are relatively close to the chemical level. With a more important presence within our planet and the possibility of making batteries, without the need for lithium, cobalt, nickel, graphite or other materials with an impact on the environment, sodium appears as a Excellent alternative on the ecological level.

Sodium, a cheaper alternative ..

Economically, sodium-ion batteries are also the big winners. Over the years, the price of lithium has greatly evolved, from 18 to 70 euros per kilo. A higher cost than that of sodium, the demand for which is less strong. This is a way to reduce the manufacturing costs of electric automotive batteries to make consumers benefit from them.

The domain giant, CATL, announced at the beginning of the year that it would industrialize sodium-ion batteries during the year 2023. Being one of the main manufacturers of electric car batteries, this means that many electric vehicles out of the factory in 2024 could be equipped with a sodium-ion battery. CATL also confirmed on April 16 that certain vehicles of the manufacturer Chery will be equipped with these famous batteries, a subject detailed by our colleagues from Frandroid on April 17.

This content is blocked because you have not accepted cookies and other tracers. This content is provided by Twitter.

To be able to visualize it, you must accept the use being operated by Twitter with your data which can be used for the following purposes: Allow you to view and share content with social media, promote development and improvement of products D’humanoid and its partners, display you personalized advertisements in relation to your profile and activity, define you a personalized advertising profile, measure the performance of the advertisements and content of this site and measure the audience of this site ( more)

Another less known advantage of these batteries is based on their low -temperature performance. Where other battery chemicals lose a good part of their capacity by winter temperatures, sodium-ion batteries are doing better. They would also recharge faster under these conditions.

On the other hand, they are heavier and less efficient

Sodium-ion batteries are not free from defects. Among the negative points of this technology, there is their energy density and their weight.

Regarding the level of performance, engineers have made progress in the field, as is the case with current lithium-ion batteries. In recent years, sodium-ion batteries have been perceived as too weak to be able to be installed in an electric vehicle. Their energy density is today quite similar to that of Lithium-Fer-Phosphate (LFP) batteries of 2014, they are therefore aimed primarily at unpropuous vehicles. Catl has announced that it has reached 200 Wh/kg. But the most interesting perhaps lies in other solutions consisting in mixing sodium ions and lithium ions to increase performance, to offer batteries with 500 km of autonomy.

In terms of weight, everything is first of all a question of chemistry: sodium is an element between 3 to 4 times heavier than lithium. Knowing that the weight of an electric car battery is easily around 300 kg depending on the number of on -board cells, this can represent a certain constraint for car manufacturers on a technical level.

Already cleaner than a thermal car, the electric car could perfect its image of green car with the use of a healthier alternative for the environment, but also less expensive for manufacturers, and therefore, for future Buyers of an electric car. New battery technology that will be followed in the coming years.

The electric automobile is a boom sector, but it still takes the keys to understanding it. Subscribe to Watt Else, the free Numerama newsletter, 100 % Wooden Wooden Guarantee on the mobility of tomorrow.

Newsletter Watt Else

You wish to receive the newsletter Watt else In your mailbox ?

Here is the new revolutionary battery of Peugeot, Citroën, Fiat, Opel and Jeep electric cars

The Stellantis group (Peugeot, Fiat, Opel, Jeep, Citroën, DS, etc.) is associated with totalnergies in order to develop an innovative technology, making it possible to offer rising autonomy to electric cars which will be equipped with it. These will also be cheaper while this solution will also be used for stationary energy storage.

The electric car may be sold better and better, to the point of exceeding diesel in Europe, many detractors still oppose their arguments there. Starting with autonomy, which remains it is true, a subject of concern for motorists. However, we know, however, that it is not useful that it is too important, quite the contrary.

A major innovation

Indeed, who says great autonomy says great battery, at least for the moment. And the greater the size, the higher the weight, which directly impacts consumption which is likely to flare. While some manufacturers and equipment manufacturers work to develop alternative solutions such as solid batteries, These will not see the light of day before the end of the decade. In the meantime, the brands choose to set up smaller packs, like Ford, but with an ultra-fast charging speed.

But others are looking for solutions that can be developed in the shorter term. This is particularly the case of the Stellantis group, which provides for all its brands become electric by 2030. If the Franco-Italian group is also interested in synthetic fuel, the development of solutions for its zero-emission cars (exhaust) is at the heart of its priorities for the moment.

This is how the firm has just announced in a press release that it has established a partnership with SAFT, a subsidiary of Totalnergies specializing in the development of advanced batteries. The two companies today reveal the fruit of their research, which lasted almost four years In collaboration with three CNRS laboratories. A vast project that required no less than ten million euros in investments, half financed by the government.

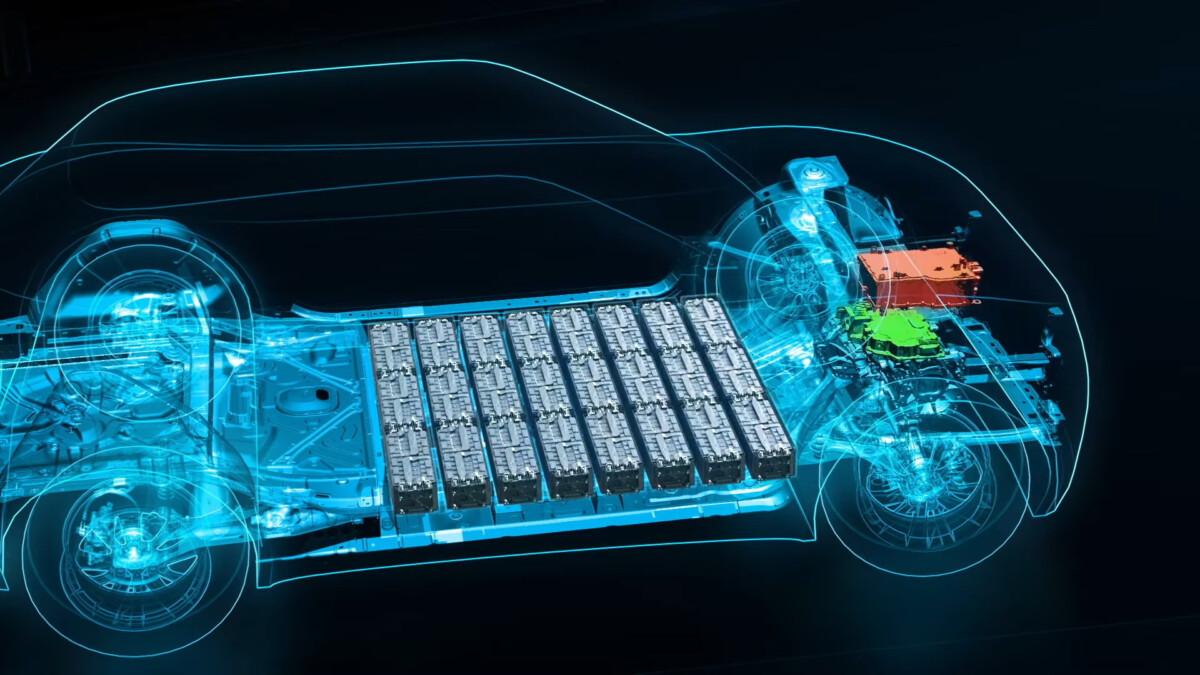

The result is called IBIS, who is none other than the acronym of Intelligent Battery Integrated System (Integrated intelligent battery system). For the time being, it takes the form of a stationary demonstrator, but ultimately this technology will be integrated into future electric cars of the group’s brands, from Peugeot to Fiat via Jeep and Citroën.

Lighter and cheaper cars

But concretely, what this research project consists of ? The latter takes the form of a technology adaptable to all types of batteries, whether it is a LFP (lithium – iron – phosphate) or NMC (Nickel – Manganese – Cobalt) technology). This one replaces the only charger and the only inverter with electronic cards climbing closer to lithium-ion cells. An alternating current supplying the engine is then created directly from the batteries.

This device allows considerably reduce the weight of the battery and its size. Which is repercussions in the production cost and makes it possible to reduce the price of cars for customers. In addition, this system increases the autonomy by approximately 12 % and offers more power for the same amount of energy. In addition, the latter is more reliable and makes it possible to increase the lifespan of cells.

This content is blocked because you have not accepted cookies and other tracers. This content is provided by YouTube.

To be able to visualize it, you must accept the use being operated by YouTube with your data which can be used for the following purposes: Allow yourself to view and share content with social media, promote development and improvement of products D’humanoid and its partners, display you personalized advertisements in relation to your profile and activity, define you a personalized advertising profile, measure the performance of the advertisements and content of this site and measure the audience of this site ( more)

Finally, it would also allow Climb the power that can be cashed by the battery During the charge according to AFP information, relayed by the site Knowledge of Energies. A first prototype should be installed and tested in an electric car in the group by next year, but we do not yet know the date on which this device will be established on a serial model.

In addition, this technology will also be used for stationary energy storage, by offering a reduced ground grip as well as easier maintenance. An essential innovation, while the needs in this area are increasing, since this solution makes it possible to depend less on the electrical network, currently under tension. Concretely, the energy is accumulated when it is used less and then reused when it is more requested. In addition, it saves money, storing electricity during off -peak hours and using it in full hours.

Do you use Google News (News in France) ? You can follow your favorite media. Follow Frandroid on Google News (and numerama).